Kempinski Hotel Corvinus, Budapest

Granuldisk solution at Kempinski Hotel Corvinus, Budapest, Hungary.

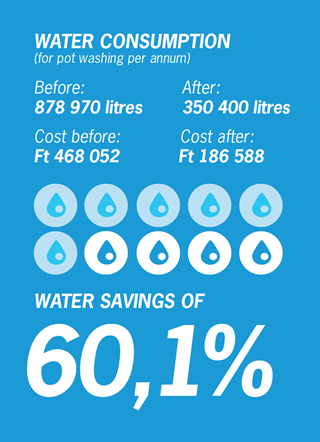

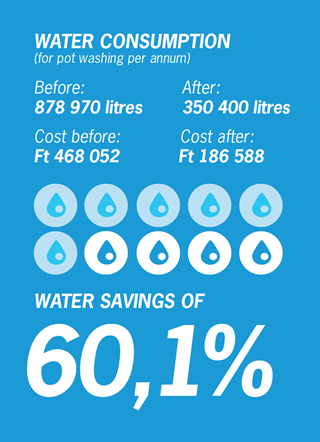

Discover how this hotel managed to save 60% water with a solution from Granuldisk.

Discover how this hotel managed to save 60% water with a solution from Granuldisk.

Soaking and manual pot washing in sinks and daily consumption of 2,408 litres of water.

An average of 400–600 hot meals is served per day in the various gastronomic outlets of the hotel. The pot washing in the kitchen is done using a 3-bowl sink system, which means manual soaking of utensils for hours, scrubbing, rinsing, and then sanitizing in a chemical dip. All the while leaving the water tap flowing resulting in wet, slippery floors, not to mention the need for constant mopping of the floor. This setup is time-consuming and uses massive amounts of water, energy to heat the water, and chemicals.

As with a lot of commercial kitchens, the Kempinski also suffers from a common problem, which is the difficulty in finding staff to perform simple kitchen tasks and avoiding high staff turnover, which is both interruptive and very costly.

Washing in a Granule Smart, running on average 26 wash cycles/day and using only 960 litres of water a day - a 60% water-reduction in the pot wash process.

The Granule Maxi pot washer went to work on its first day, and its positive effects were felt right from the get go. The Granule technology enables the kitchen porters to return the pots and pans to the chefs at a faster rate. For example, four pieces of GN 2/1 can be washed and sanitized in 2 to 6 minutes, depending on which wash cycle chosen.

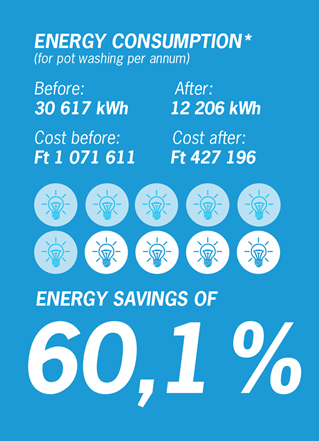

Water consumption is down by 60% in the pot-washing area, and consequently, there is also a reduction in electricity and chemical consumption.

The trial also proved beneficial because the hotel no longer has to worry much about its workforce. The hotel now has a reliable solution that can handle the washing and sanitization of large volumes of pots and pans within a limited time frame. Maintaining excellent food safety standards in the hospitality industry is of crucial importance, and if left unchecked poor safety practices can cost companies thousands of euros in fines.

Thanks to Granuldisk, Chef Holzer now can be confident that his pots and pans are properly sanitized every time. Plus additional benefits that wares are circulated back to chefs much quicker which is crucial during peak cooking periods. Last but not least, the wash result is impeccable.

* Consumption calculated from water consumption

Curious about what you would save by switching to a Granuldisk solution in your kitchen? Let us calculate your savings in a Business Evaluation and find out!

Book a free consultation →